How To Select The Right Contract Manufacturer

March 6, 2018

Choosing the right contract manufacturer is a critical decision to ensure your project is delivered on time and within budget. And whilst many companies may appear attractive it is important to assess all aspects to make sure they are not only fit for purpose but also right for you, your company, your values and your project.

Here we provide a short guide on areas to consider:

Quality:

Always insist on a quality standard, whilst internal quality systems are important and valid we would always recommend working with a contract manufacturer that has externally and independently accredited quality systems, in particular ISO9001:20151, this recently updated standard is based on quality management principles including a customer focus and approach for continual improvement.

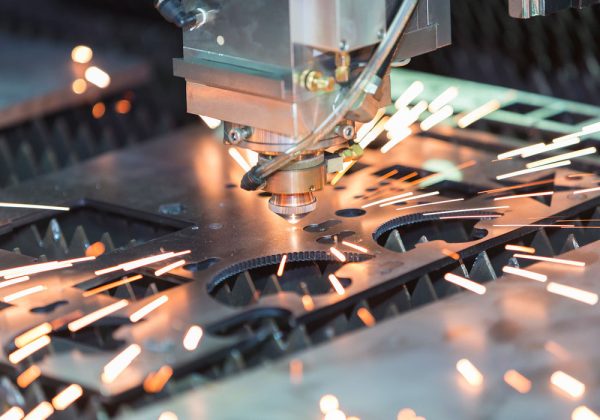

Technology and Equipment:

Look at the plant list provided by the companies you are considering. Do they have the capabilities to produce what they are promising and what you need? Confirm if equipment is in-house or if they have to use other external contractors to fulfill production. This simple investigation will help build your confidence in your chosen contractor.

History and stability:

The worst outcome is for your project timeline is for it to be derailed by a supplier going out of business. In today’s uncertain economy this is unfortunately more of a possibility than any of us would wish for. Look for a company with a long history and strong financial foundation that can survive the turbulent market conditions and that you know will be with you for the long term.

It’s all about you:

Remember this is your project and whilst you are looking to partner with a sub-contractor for their expertise, the focus needs to be on delivering your project and not their version of what they think you require or can manufacture. Go with your instincts on this, if you feel from the initial conversations that they haven’t got your priorities at the heart of the project don’t progress further.

The team:

Ask about the collective experience of the team who will be responsible for your project. Look for teams that have many years of service both in the company and industry, this shows stability in the company and a depth of knowledge. Look for project teams that provide a variety of expertise from design to engineering and finishing. If your only point of contact is a sales person, ask why?

Good Industry Mix:

Whilst most companies grow by developing a specialism in one particular market look for manufacturers who have gained experience in a wider industry mix. This brings new technologies and new approaches and also spreads the risk, increasing the financial stability mentioned previously.

Honesty:

Again gut instincts play a huge role here, trust them. If you have any feeling that the company is not being 100% honest with you double check and change before it’s too late and before your project is impacted.

So what next… research potential contract manufacturers via internet searches, exhibitions and industry associations, not forgetting recommendations. Make your list, make contact and make a note of initial responses. Undertake the investigations as advised here and make your selection.

Contract manufacturing services from Dudley Industries

If you are looking for contract manufacturing support contact us today and our experienced team will guide you through the process from design, to prototype to full scale production. Our mantra is to continually improve and our quality procedures are accredited through ISO9001:2015. So whatever your requirements are we’ll be there for you.

[1] https://www.iso.org/iso-9001-quality-management.html